Okhla, New Delhi

- GST NO. : 07AAACU4584E1ZB

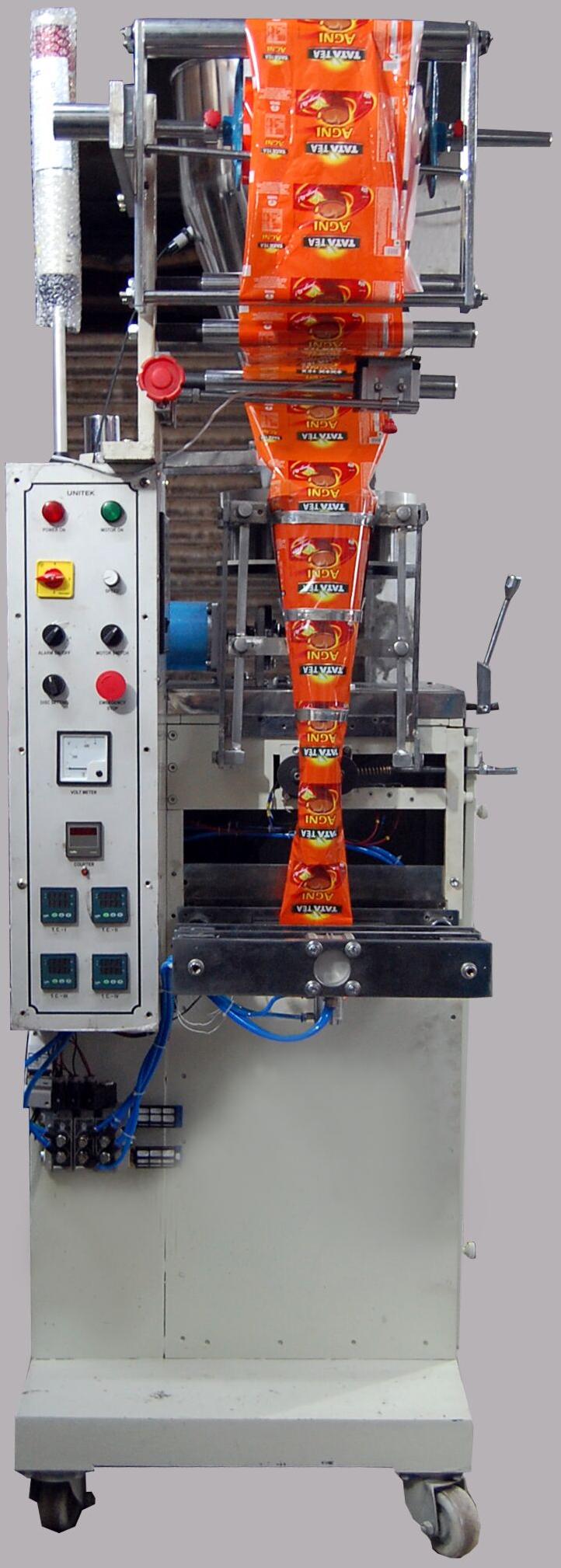

FFS Machine

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of FFS Intermittent Liquid Machine, FFS Intermittent Machine with Linear Feeder, FFS Intermittent Machine with Weigher, FFS Intermittent PLC Operated Machine, FFS Pneumatic Machine and Pneumatic FFS Machine from New Delhi.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler, Trader |

| Model Number | UT - 54 |

| Product Application | Liquid/ Paste/ Ketchup/ Lubrication oil/ Shampoo/ Gel |

| Sealing Type | 4 Side Seal / 3 Side Seal |

| Packing Size | 1– 5 ml, 5-20 ml, 20-50ml, 50-100ml |

| Feeding System | Dosage Pump |

| Packaging Speed | 30-55/ Min |

| Main Motor | 1 H.P. |

| Heater Load | 150 W – 4pcs / 300 W – 2 pcs |

| Laminate | Heat Sealable Laminate Filmcore Dia 75 Mm / Max Outer Dia 350 Mm |

| Contact Parts | Stainless Steel |

| Power Consumption | 3 Kw 220V -50Hz |

| Machine Dimension | L. 1000 x W. 900 x H. 2000 ( mm) |

| Net Weight | 450 Kgs ( Approx.) |

| Optional Attachments ( At an extra cost) | Electronic contact coder.Out feed conveyor. S.S. Cladding |

| Air Compressor | 6 CFM |

| Payment Terms | Other |

Preferred Buyer From

| Location | Worldwide |

Features

- Electronic Control panel

- Pre programe control panel

- Photo Sensor for perfect sealing.

- Change of length of pouch by press of button.

- Adjustable liquid dosage pump.

- Intermittent horizontal and vertical sealing station.

- Inbuilt batch cutting mechanism.

- Noiseless Performance.

- Contact parts in Stainless Steel.

- Durable Mechanical Structure.

- Superior pouch finish

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler, Trader |

| Model Number | UT - 58 |

| Product Application | Namkeen , Kurkure, Cheese Ball |

| Sealing Type | Center Seal |

| Packing Size | 10-100 gms |

| Feeding System | Volumetric Cup Filler |

| Speed | 300/ min |

| Main Motor | 1⁄2 H.P. 50 Hz Single phase |

| Heater Load | 150 W – 2pcs / 300 W – 2 pcs |

| Laminate | Heat sealable laminate film Core dia 75 mm / Max outer dia 350 mm |

| Contact Parts | Stainless Steel |

| Power Consumption | 2 Kw 220V - 50Hz |

| Machine Dimension | L. 1000 x W. 910 x H. 2300 ( mm) |

| Net Weight | 450 Kgs ( Approx.) |

| Optional Attachments ( At an extra cost) | Electronic contact coder. Out feed conveyor |

| Air Compressor | 6 CFM |

Preferred Buyer From

| Location | Worldwide |

Features :

- Electronic control panel with Pid temp controller change of length of pouch by press of button.

- Linear feeder for smooth flow of product,

- Level Sensor is in corporated to maintain regular feed of material.

- AC Drive to regulate the speed of the machine in accordance to the size of the pouch and the characteristic and the density of the product.

- Pneumatic sealing station with batch cutting mechanism.

- Adjustable Dosage Plates for high accuracy.

- Nitrogen Flushing.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler, Trader |

| Model Number | UT - 59 |

| Product Application | Dry fruits, vermicelli, kurkure |

| Sealing Type | Centre Seal |

| Packing Size | 50-250 gms , 250 – 500 gms, 500 – 1000 gms |

| Feeding System | Load cell Weighed |

| Speed | 6-15/ min ( Depending upon number of heads) |

| Main Motor | 1 H.P. 50 Hz |

| Heater Load | 150 W – 2pcs / 300 W – 2 pcs |

| Laminate | Heat sealable laminate film Core dia 75 mm / Max outer dia 350 mm |

| Contact Parts | Stainless Steel |

| Power Consumption | 3 Kw 220V - 50H |

| Machine Dimension | L. 1000 x W. 910 x H. 1560 ( mm) |

| Net Weight | 600 Kgs ( Approx.) |

| Optional Attachments ( At an extra cost) | Electronic contact coder. Out feed conveyor. Nitrogen Gas Flushing |

| Air Compressor | 6 CFM |

Preferred Buyer From

| Location | Worldwide |

Features :

- AUTO SHUT OFF SYSTEM In the event of heater failure the machine automatically halts and the indication is given through the tower light.

- PLC with Touch Screen HMI

- Teaching Scanner.

- AC Drive to regulate the speed.

- Emergency Stop.

- Inbuilt Batch cutting

- Nitrogen Flushing

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler, Trader |

| Model No. | UT - 56 |

| Product Application | Free Flowing Granules |

| Sealing Type | Center Seal / Three Side Seal |

| Packing Size | 5-25 gms / 25-100gms / 100-500gms |

| Feeding System | Motorised Cup Filler |

| Packaging Speed | 20-55/ Min |

| Main Motor | 1 H.P.& 0.5 H.P. ( Two Motors) |

| Heater Load | 150 W – 2pcs / 300 W – 2 pcs |

| Laminate | Heat sealable laminate film |

| Contact Parts | Core dia 75 mm / Max outer dia 350 mm Stainless Steel |

| Power Consumption | 3 Kw 220V - 50Hz |

| Machine Dimension | L. 1000 x W. 910 x H. 2150 ( mm) |

| Net Weight | 400 Kgs ( Approx.) |

| Optional Attachments ( At an extra cost | Auger filler, Electronic contact coder. Out feed conveyor. |

| Air Compressor | 6 CFM |

Preferred Buyer From

| Location | Worldwide |

Features :

- PLC with Color Touch Screen

- Pid temperature controller

- Motoriz ed unwinding assembly

- Vector drive for smooth pulling

- Independent motor for Dosage plates

- Material level sensor no product no operation

- Inbuilt batch cutting mechanism

- Nitrogen flushing

- Emergency Stop

MOQ : 1 Piece(s)

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler, Trader |

| Voltage | 220V |

| Automatic Grade | Automatic |

| Power | 1-3kw |

| Driven Type | Electric |

| Warranty | 1year |

| Usage | Food Packaging |

| Payment Terms | Other |

Preferred Buyer From

| Location | Worldwide |

Unitek offers the most extensive range of Form Fill Seal Machines ffs pneumatic machine is ideal for packing products which are hydroscopic , the machine provides perfect seal, superior sachet finish, inbuilt with batch cutting facility the speed of the machine can be varied by rotating the knob, besides the machine is equipped with material level sensor and auto shut off system.

MOQ : 1 Piece(s)

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler, Trader |

| Payment Terms | Other |

Preferred Buyer From

| Location | Worldwide |

FFS Pneumatic machine state of the art of technology comprises with most advanced features at economical cost to pack free flowing products in pouches. The Machine comprises of pneumatically operated vertical and horizontal sealing machine with single head load cell weigher to weigh the product and dispense it in the pouch.

Features:

- AUTO SHUT OFF SYSTEM – In the event of heater failure the machine automatically halts and the indication is given through the tower light.

- PLC interfaced with weigher and bagging machine

- AC Drive to regulate the speed.

- Emergency Stop.

- Inbuilt Batch cutting

Optional Attachments (At an extra cost)Electronic contact coder.

Out feed conveyor.

Nitrogen Gas Flushing